-

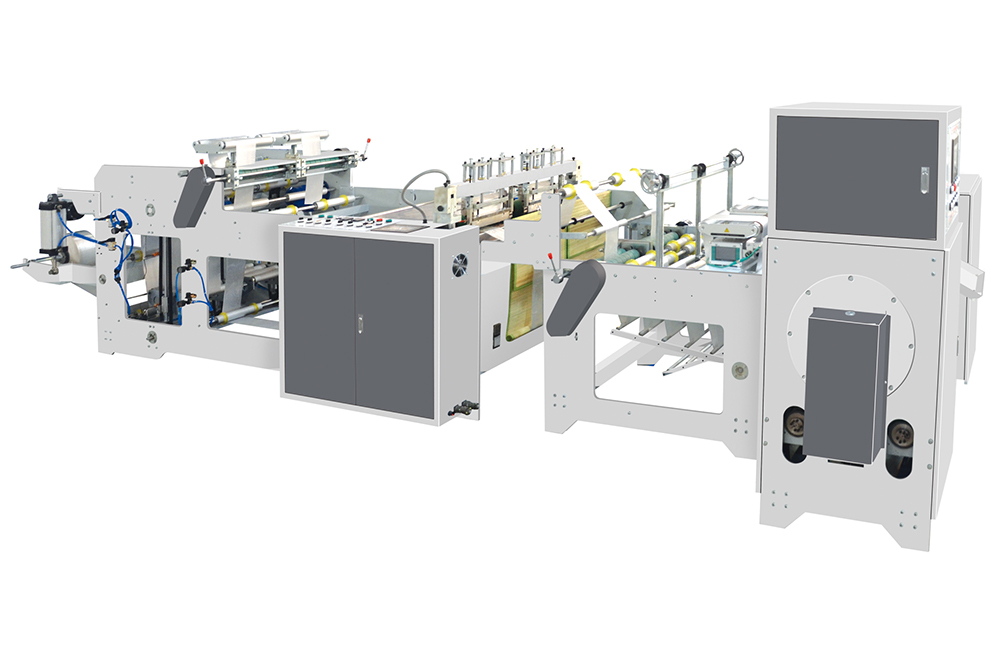

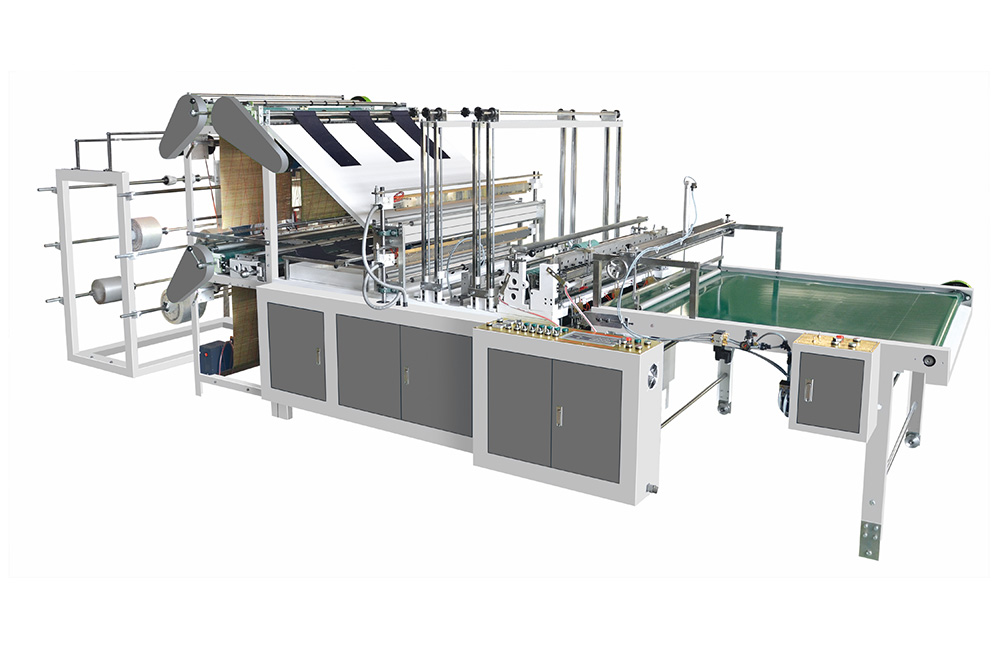

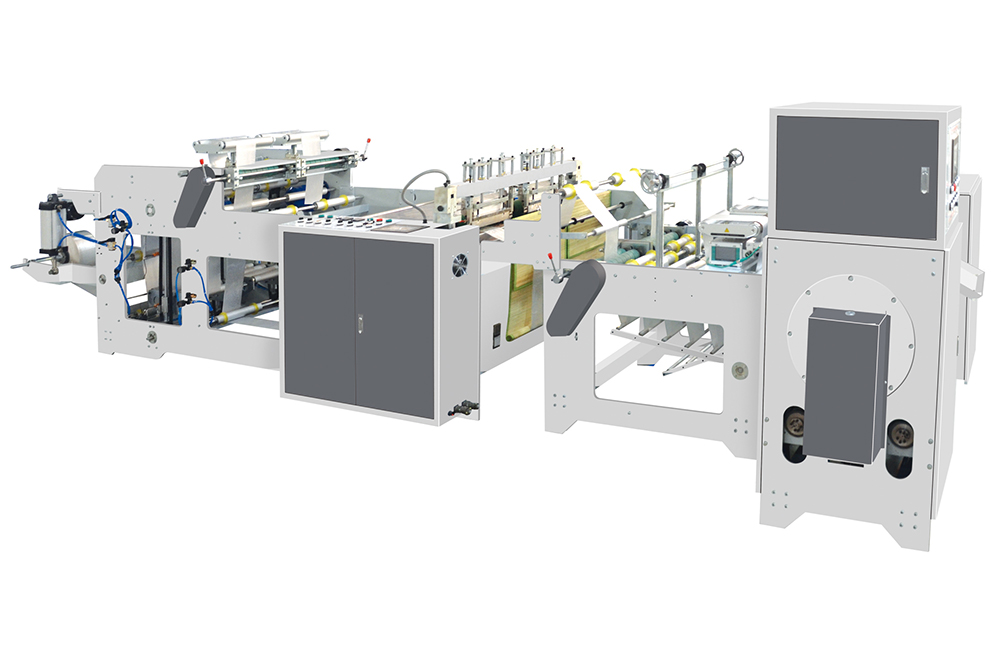

bottom seal flat bag small

-

bottom seal flat bag small

-

bottom seal flat bag small

-

bottom seal flat bag small

|

Items |

GBD-700*6 |

GBD-800*6 |

GBD-900*6 |

|

Work line |

Two decks, six lines |

Two decks, six lines |

Two decks, six lines |

|

Bag making length |

100-400mm |

100-600mm |

100-800mm |

|

Bag making width |

100-150mm*6 |

100-200mm*6 |

100-250mm*6 |

|

Output |

20-140pcs/min*6 |

||

|

Total Power |

9kw |

9.5kw |

10kw |

|

Model name |

Multiline bottom seal bag making machine |

|

Final product |

Bottom seal bag, bottom seal bag with punch hole |

|

Application |

Printed,unprinted flat bag and freezer bag(bottom seal bag),piece by piece bag, |

|

Material |

HDPE, LDPE, LLDPE ,BIO,recycled material, CaCO3 compound, masterbatch and additives |

|

Output range |

20-140pcs/min x6 |

|

Delivery time |

30-60days |

|

Warranty |

1 year |

|

Technical assiatance |

Oversea Machine commissioning services are available. |

This bottom seal bag making machine equipped with hot sealing knife and cold cutting knife which is heavy and stainless. Due to it’s durable and high-quality knives, bags can be cut off evenly with a firmly sealed bottom, the maximum film thickness even can reach at 200 micron. Because of the machine has two decks up and down, and rubber roller is wide enough to produce four line bottom seal bags in decks up and down.

On this bottom seal bag making machine, unwinder is come with AC motor inverter controlled, film feeding contolled by Taiwanese servo motor, high-precision cold cutting knife. All of these are made the bottom seal bag making machine work durable and more efficient.